- Cashew grading machine

Cashew Grading Machine | Cashew Grader Machine | Grading Machine for Cashew Nuts Precision Unleashed: Elevate Your Cashew Grading with Cosmos Grading Machine

Explore the future of cashew grading with Cosmos, where each nut is meticulously sorted to meet the highest standards of quality.

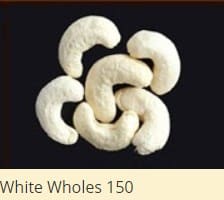

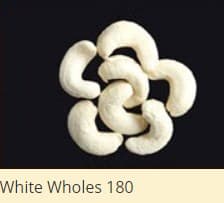

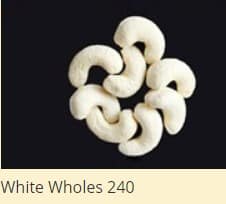

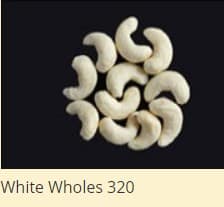

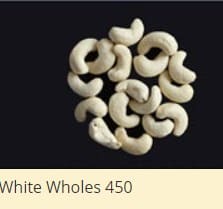

Popular Grades

Vivid Precision: Unleashing Excellence with Our Cashew Grading Machine

Welcome to Cosmos Color Sorter, where technological innovation meets the cashew industry’s grading needs. Our Cashew Grading Machine, located in the bustling city of Coimbatore, Tamil Nadu, India, is not just a machine; it’s a commitment to excellence.

Unveiling the Technological Marvel Behind Cosmos Cashew Grading Machine

Cashew Nut Grading Machine Price

Automatic Calibration for Pinpoint Precision

Experience grading at its best with our Cashew Grading Machine, featuring automatic online calibration with self-check procedures. Achieve pinpoint precision in grading without the hassle of manual adjustments.

Trichromatic RGB Cameras for Unmatched Vision

Equipped with trichromatic RGB cameras (Red, Green & Blue) boasting a very high resolution of 16,200 pixels, our machine utilizes cutting-edge image processing technology for unparalleled grading accuracy.

Ultra-Fast Pneumatic Ejectors for Swift Sorting

Swiftly sort cashews with ultra-fast pneumatic sniper ejectors, boasting a response time of 1000 per second and a life span of up to 4 billion cycles. Benefit from high-speed, reliable sorting with every cycle.

Shape & Size Sorting for Tailored Excellence

Tailor your cashew grading with shape and size sorting options. From j, jh, k, s to swp, lwp, ssp, and various grades like W180, W210, W240, W320, W450—our machine ensures tailored excellence to meet diverse industry demands.

Wireless Control for Modern Convenience

Embrace modern convenience with wireless control. Our machine can be accessed and controlled through your smartphone via wireless LAN, offering flexibility and control at your fingertips.

24x7 Service for Uninterrupted Operations

Our commitment goes beyond the machine. Benefit from 24x7 service availability, ensuring that your Cosmos Cashew Grading Machine operates seamlessly whenever you need it.

Features

- Quality Sorting

- Removal of Defective Nuts

- Enhanced Food Safety

- Increased Efficiency

- Optimizing Production Costs

Benefits

- Uniform Color Consistency

- Sorting by Grades

- Adaptability to Different Varieties

- High-Grade Cashew Sorter

- Efficient Cashew Grading

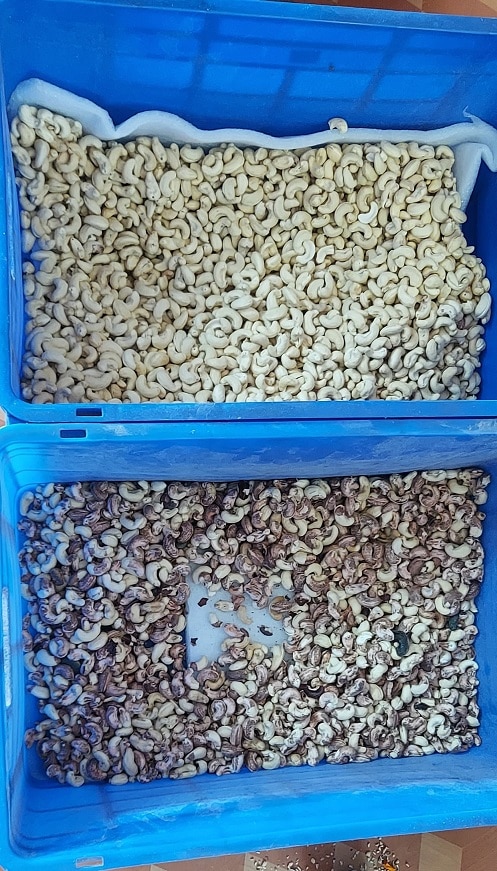

Cashew Kernel Grading Machine

Cashew Shelling Sorting.

Automatic Cleaning and LED Lighting

Ensure a clear view and stable illumination with automatic cleaning of the camera viewing area and LED solid-state high-intensity lighting, contributing to extended machine life.

Chute Heating System for Uninterrupted Flow

Experience uninterrupted grading with our innovative chute heating system. Designed to ensure a free flow and prevent choking of running materials, this feature enhances the efficiency of your cashew processing line.

User-Friendly Interface for Effortless Operation

Navigate grading effortlessly with easy machine settings and a user-friendly interface. Access and control your machine effortlessly, even through your smartphone via wireless LAN.

100 Pre-Set Programs for Versatility

Versatility is the key, and with 100 pre-set programs, our Cashew Grading Machine adapts to your diverse grading needs. Easily switch between different cashew grades and sizes with a simple selection.

Revolutionizing Cashew Quality: Cosmos Cashew Grading Machine Sets a New Standard

Economic Advantage: Machine Longevity and Operation Cost

The Perfect Blend of Longevity and Cost-Efficiency: Cosmos Cashew Grading Machine’s Economic Advantage. The evolution of cashew grading technology has been a journey from traditional sorting methods to the sophisticated precision offered by modern machines. Cosmos Cashew Grading Machine stands at the forefront of this technological revolution, employing cutting-edge features that redefine the cashew grading landscape.

Advancements in Cashew Grading Technology

The trichromatic RGB cameras, a cornerstone of our grading machine, capture high-resolution images with unparalleled detail. These images serve as the basis for intricate analyses, considering not just size but also color and shape variations among cashews. The result is a level of precision that was once unimaginable, ensuring that each cashew is sorted according to the most rigorous quality standards.

COSMOS COLOR SORTER

Cost Effective Cashew Grading Machine

The use of image processing technology further enhances the capabilities of our machine. Advanced algorithms process the captured images in real-time, making split-second decisions on the acceptance or rejection of each cashew. This real-time processing is crucial in maintaining the pace of modern cashew processing lines, where efficiency is paramount.

One of the standout features is the automatic calibration system with self-check procedures. This innovation eliminates the need for manual adjustments, ensuring that the machine maintains optimal performance with minimal human intervention. This not only reduces the margin for error but also simplifies the operation, making it accessible even to operators with limited experience.

Shape and size sorting capabilities add a layer of versatility to our Cashew Grading Machine. Whether you’re dealing with the larger W320 or the smaller W180, our machine adapts to the unique characteristics of each grade. The ability to customize sorting criteria based on different cashew varieties reflects a commitment to meeting the diverse needs of the cashew industry.

The ultra-fast pneumatic sniper ejectors are a testament to the engineering excellence embedded in our grading machine. With a response time of 1000 per second and a remarkable lifespan of up to 4 billion cycles, these ejectors ensure swift and reliable sorting. The rejection ratio of 10:1 speaks volumes about the machine’s ability to discern even the slightest imperfections.

Cosmos Color Sorter’s commitment to sustainability is reflected in the design of the machine. The chute heating system ensures a free flow of cashews, avoiding choking and blockages. This not only contributes to operational efficiency but also minimizes the risk of downtime, a crucial factor in the fast-paced cashew processing industry.

Wireless control adds a layer of modern convenience, allowing operators to access and control the machine through a smartphone via wireless LAN. This feature enhances flexibility, enabling operators to monitor and adjust the grading process even when not physically present at the machine.

Service availability around the clock ensures that the benefits of our Cashew Grading Machine are not bound by time constraints. Whether it’s day or night, our dedicated team is ready to address any concerns and ensure that your machine operates seamlessly, contributing to uninterrupted cashew processing.

Frequently Asked Questions

Everything you wanted to know about Cashew Nut Kernel Grading Machine.

Cashews are graded based on their size, shape, and quality. The grading system typically involves categorizing cashews into different sizes and grades, with larger and whole kernels often receiving higher grades. Common grades include W180, W240, W320, and so on, where “W” stands for “white” and the number represents the quantity of kernels per pound.

The “W” designation in cashew grades refers to the number of kernels per pound. Therefore, W400 denotes that there are approximately 400 kernels per pound, while W450 signifies around 450 kernels per pound. In general, a lower W number implies larger and more whole kernels. Whether W400 or W450 is considered “better” depends on the specific requirements of the end product and consumer preferences. Some may prefer larger, whole kernels for certain applications, while others may find smaller sizes more suitable.

The highest grade of cashew nuts is often considered to be W180, where there are approximately 180 kernels per pound. W180 cashews are typically larger, whole kernels and are often sought after for their premium quality. However, the “highest grade” can vary based on specific market preferences and uses.

The main difference between cashew 240 and 320 lies in the size and quantity of kernels per pound. Cashew 240 means there are approximately 240 kernels per pound, while cashew 320 signifies around 320 kernels per pound. Generally, cashew 240 will have larger and fewer kernels compared to cashew 320. The choice between the two depends on the desired size and appearance for a particular application or market demand. Both grades can be suitable for various purposes, and the preference may vary among consumers and manufacturers.

Important Tags

grader, cashew grader, grading cashew, machinery, sorting machine, cashew grading machines, cashew sorting machine, cashews, automatic cashew, kernel grading, optical sorting, cashew sorting, cashew kernel cashew nut, grader, grading cashew, machinery, cashew nut, sorting machine, cashew grading machines, automatic cashew, kernel grading, sorter machine, nut processing, grader cashew, cashew optical, optical sorting, cashew sorting, cashew kernel, nut, ebrochure, cashew nut, peeling machine, shelling machine, processing machine, nut shelling, cashew nuts