- COSMOS Cashew Sorting Machine

Cashew Sorting Machine | Cashew Grading Machine Efficient Cashew Grading | High-Grade Cashew Sorter

Color sorters play a crucial role in the cashew nut processing industry, ensuring the production of high-quality and visually appealing cashew nuts

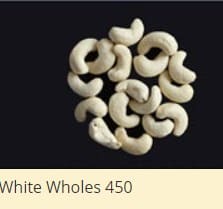

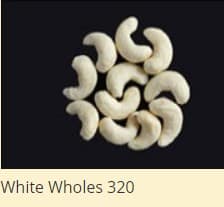

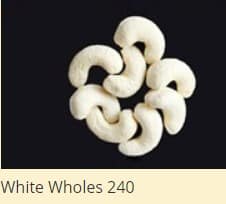

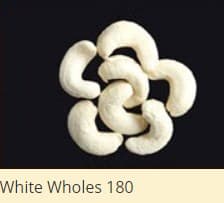

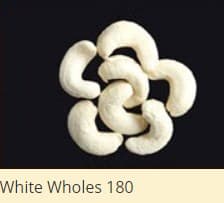

Popular grades

Vivid Precision: Unleashing Excellence with Our Cashew Sorting Machine

Welcome to Cosmos Color Sorter, where technological innovation meets the cashew industry’s gsorting needs. Our Cashew Sorting Machine, located in the bustling city of Coimbatore, Tamil Nadu, India, is not just a machine; it’s a commitment to excellence.

Unveiling the Technological Marvel Behind Cosmos Cashew GSorting Machine

Cashew Nut Grading Sorting Price

Automatic Calibration for Pinpoint Precision

Experience grading at its best with our Cashew Grading Machine, featuring automatic online calibration with self-check procedures. Achieve pinpoint precision in grading without the hassle of manual adjustments.

Trichromatic RGB Cameras for Unmatched Vision

Equipped with trichromatic RGB cameras (Red, Green & Blue) boasting a very high resolution of 16,200 pixels, our machine utilizes cutting-edge image processing technology for unparalleled grading accuracy.

Ultra-Fast Pneumatic Ejectors for Swift Sorting

Swiftly sort cashews with ultra-fast pneumatic sniper ejectors, boasting a response time of 1000 per second and a life span of up to 4 billion cycles. Benefit from high-speed, reliable sorting with every cycle.

Ultra-Fast Pneumatic Ejectors for Swift Sorting

Swiftly sort cashews with ultra-fast pneumatic sniper ejectors, boasting a response time of 1000 per second and a life span of up to 4 billion cycles. Benefit from high-speed, reliable sorting with every cycle.

Shape & Size Sorting for Tailored Excellence

Tailor your cashew grading with shape and size sorting options. From j, jh, k, s to swp, lwp, ssp, and various grades like W180, W210, W240, W320, W450—our machine ensures tailored excellence to meet diverse industry demands.

Wireless Control for Modern Convenience

Embrace modern convenience with wireless control. Our machine can be accessed and controlled through your smartphone via wireless LAN, offering flexibility and control at your fingertips.

24x7 Service for Uninterrupted Operations

Our commitment goes beyond the machine. Benefit from 24x7 service availability, ensuring that your Cosmos Cashew Grading Machine operates seamlessly whenever you need it.

24x7 Service for Uninterrupted Operations

Our commitment goes beyond the machine. Benefit from 24x7 service availability, ensuring that your Cosmos Cashew Grading Machine operates seamlessly whenever you need it.

Features

- Automatic online calibration with self-check procedures

- Fully computer controlled and image processing technology. Trichromatic RGB camaras (Red,Green&Blue) are used.

- Very High resolution with 16200pixels, CCD Lineinspection Scan cameras (from 0.05mm onwards)

- LED solid state high intensity long life stable lightning

- On-line live visual display of product being sorted on 8” Color LED TFT Screen.

- Ultra- fast long life pneumatic sniper ejectors with response time of 1000 per second and life upto 5 billion cycles

- High speed serviceable Ejectors

Benefits

- Automatic cleaning of Camera viewing area by wiper system

- Shape & size sorting available( like j,jh,K,s,swp,lwp,ssp AND W-180,W-210,W-240,W-320,W-450) Best rejection ratio(10:1) and reverse resorting available.

- Cashew Shell Sorting Available

- Longer machine life & lower operation cost

- Chute heating system to ensure free flow & avoid chock of running materials. Easy machine settings/User –friendly interface

- Machine can access/control through smartphone via wireless LAN 100 Pre Set Programs Available

- Service Available 24*7

Cashew Kernel Sorting Machine

Cashew Shelling Sorting.

Automatic Cleaning and LED Lighting

Ensure a clear view and stable illumination with automatic cleaning of the camera viewing area and LED solid-state high-intensity lighting, contributing to extended machine life.

Chute Heating System for Uninterrupted Flow

Experience uninterrupted grading with our innovative chute heating system. Designed to ensure a free flow and prevent choking of running materials, this feature enhances the efficiency of your cashew processing line.

User-Friendly Interface for Effortless Operation

Navigate grading effortlessly with easy machine settings and a user-friendly interface. Access and control your machine effortlessly, even through your smartphone via wireless LAN.

100 Pre-Set Programs for Versatility

Versatility is the key, and with 100 pre-set programs, our Cashew Grading Machine adapts to your diverse grading needs. Easily switch between different cashew grades and sizes with a simple selection.

Revolutionizing Cashew Quality: Cosmos Cashew Sorting Machine Sets a New Standard

Economic Advantage: Machine Longevity and Operation Cost

The Perfect Blend of Longevity and Cost-Efficiency: Cosmos Cashew Sorting Machine’s Economic Advantage. The evolution of cashew sorting technology has been a journey from traditional sorting methods to the sophisticated precision offered by modern machines. Cosmos Cashew Sorting Machine stands at the forefront of this technological revolution, employing cutting-edge features that redefine the cashew sorting landscape.

Advancements in Cashew Sorting Technology

The trichromatic RGB cameras, a cornerstone of our Sorting machine, capture high-resolution images with unparalleled detail. These images serve as the basis for intricate analyses, considering not just size but also color and shape variations among cashews. The result is a level of precision that was once unimaginable, ensuring that each cashew is sorted according to the most rigorous quality standards.

Frequently Asked Questions

Everything you wanted to know about Cashew Nut Kernel Sorting Machine.

Sorting cashew nuts is a meticulous process that involves several steps to ensure only high-quality nuts make it to the final product. The primary method employed for sorting cashew nuts is through the use of advanced color sorting machines. These machines utilize optical sensors, such as RGB cameras or hyperspectral imaging, to distinguish between nuts based on color, size, and quality. As the nuts move along a conveyor belt, the sensors capture detailed information, enabling the machine to make split-second decisions about each nut’s classification. Defective or discolored nuts are then separated from the main stream using precision ejector mechanisms, resulting in a sorted batch of cashews ready for further processing.

Grading cashew nuts is a crucial step in categorizing them based on various factors such as size, color, and quality. The grading process typically involves the following steps:

Size Sorting: Cashew nuts are sorted into different size categories using sieves or screens. Common size classifications include large, medium, and small.

Color Sorting: Advanced color sorting machines are employed to categorize cashews based on their color. This ensures uniformity in appearance and meets market preferences.

Quality Assessment: Manual inspection or automated systems assess the overall quality of cashew nuts, including factors like completeness, shape, and the absence of defects.

Moisture Content Analysis: Grading may also involve checking the moisture content of the nuts, as it can impact shelf life and overall quality.

After grading, cashew nuts are typically organized into different grades or categories, each meeting specific criteria to cater to diverse market preferences.

Processing cashews from a tree involves several steps, and it is a labor-intensive process. Here’s an overview of the key steps:

Harvesting: Cashew nuts grow attached to a cashew apple. Harvesters manually pick the cashew apples from the tree, ensuring the nuts are still attached.

Separation: The cashew nuts are separated from the cashew apples. This is often done manually or by using simple tools.

Drying: The separated nuts are then dried in the sun to reduce moisture content. This step is crucial for preventing mold and ensuring the nuts can be stored without spoilage.

Shelling: After drying, the outer shell of the cashew nut, known as the cashew nut shell (CNS), is removed. Traditionally, this has been a manual process, but there are also machines available for shelling.

Peeling: The inner skin or testa is peeled from the cashew kernel. This can be done manually or with the help of machines.

Grading and Sorting: The processed cashew nuts are graded and sorted based on size, color, and quality, often utilizing advanced color sorting machines.

Packaging: The final step involves packaging the processed cashew nuts into bags or containers, ready for distribution and consumption.

Yes, cashews can be shelled by machine. Shelling machines have been developed to automate the process, making it more efficient and less labor-intensive. These machines use mechanical or pneumatic mechanisms to crack open the hard cashew nut shell, allowing for easier removal of the kernel. Shelling machines are particularly valuable in large-scale cashew processing operations, where the volume of nuts makes manual shelling impractical. The use of shelling machines enhances overall processing efficiency, reduces labor costs, and contributes to higher production yields.

Important Tags

sorter machines, supplier, cashew color sorter, cashew color, nuts, kernels

sorting machines, machines, sorter, sorting machine,color, cashew color sorter, Cashew sorting machine price, rice color sorting machine, meyer color sorter, meyer sortex price in india, tea color sorter machine

CONTACT FORM

We understand selecting the ideal cashew processing machinery is a crucial decision for your business. Filling our simple contact form will help us grasp your requirements accurately and suggest customized solutions for long-term efficiency gains. Our team will get in touch shortly to initiate the best pricing and features discussion for your upgrade needs.